Product Gallery

e555ebe0ce42

Panel and Pattern Plating Production Line

Deprecated: WC_Product::list_attributes is deprecated since version 3.0! Use wc_display_product_attributes instead. in /home/cp42797/public_html/wp-includes/functions.php on line 4779

Capacity

Country

More Info

- Description

Fully automatic line for production of printed circuit boards one circulating air dryer with 3 working positions • 8 copper and 1 tin stations • 83 positions, incl. 13 Storage positions • 20 vibratory flight bars • integrated metal stripping station (2 stations) • registering a job with or without goods movement • 3 hoists with drip tray • frequency converters for variable drive and brake speeds two electroless copper tanks with semi-automatic chemistry transfer and cleaning process • line is designed for limited spaces • automatic copper dissolving station for supply of copper oxide, with crane as supporting tool • copper via filling tank with horizontal movable nozzle register for electrolytic upstream flow on printed circuit boards • last generation of insoluble anodes in all copper plating tanks • floating blending shields for different sizes of printed circuit boards • process: electroless copper, electrolytic copper with via filling and electrolytic tin.

Enquiry

- Make an Enquiry

Related products

-

Automatic Packing Machinery for Irregular Granular Products

All Industries, Machinery, Packaging Line, Packaging MachineCompare -

Packing Machinery for Granular Products

All Industries, Machinery, Packaging Line, Packaging MachineCompare -

PVC Plastic Mat Extruder Machinery

All Industries, Machinery, Plastic & Rubber Processing Machinery, Plastic ExtrudersCompare -

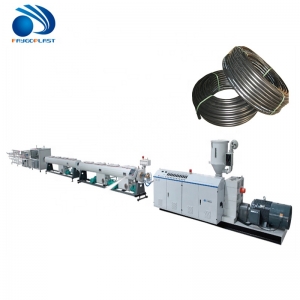

Plastic Flexible PE Pipe Extrusion Machinery

All Industries, Machinery, Plastic & Rubber Processing Machinery, Plastic ExtrudersCompare